Head Install, Vertical Check for Hosonsoft / PrintEXP

This article explains the vertical alignment verification process performed immediately after installing a new printhead. The vertical check ensures that each nozzle row is firing in a straight, properly aligned path, preventing double lines, color ghosting, and vertical misregistration during printing. It details how to run the Vertical Check test pattern, interpret results, and adjust physical Printhead until lines from each channel are perfectly aligned. The procedure focuses on fine-tuning head position itself not software registration.

Software: Hosonsoft | Scope: Physical head alignment only (no digital offsets)

Purpose

Verify and correct the printhead’s physical vertical alignment so all channels stitch straight with no left/right “splice” offset before any digital fine-tuning.

Prerequisites

-

Head mechanically installed and inked; no leaks; carriage moves freely

-

Nozzle test acceptable (≥95% firing)

-

Media: DTF film loaded; standard print mode (settings you usually use ie. Eclosion settings (Mode, Type), Print Speed (High), Print Direction (bidi)

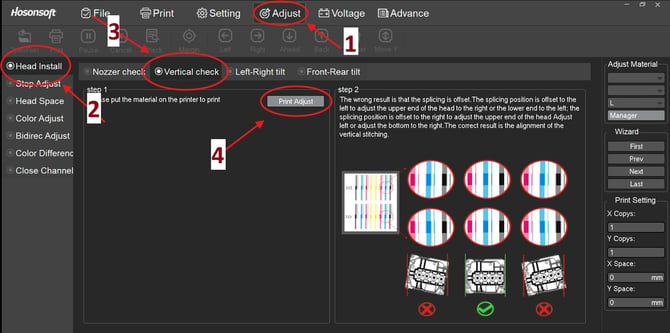

Navigation (refer to image callouts)

-

Adjust tab (top menu) — [Callout 1]

-

Head Install (left panel) — [Callout 2]

-

Vertical check (tab header) — [Callout 3]

-

Click Print Adjust to print the chart — [Callout 4]

Step-by-Step

1. Prepare media & carriage

-

-

in Control Software (Hosonsoft / PrintEXP) Go to Adjust → Head Install → Vertical check, press Print Adjust (Printer prints Calibration Chart).

-

Let the chart complete; do not move media between iterations.

-

2. Print the Vertical Check chart

-

In Adjust → Head Install → Vertical check, press Print Adjust.

-

Let the chart complete; do not move media between iterations.

3. Read Test Chart (diagnosis)

- Inspect each channel’s vertical bars.

- Correct pattern: Bars align in a straight, continuous column (see right portion of photo below labeled as step 2 for example of correctly aligned head pattern).

- Incorrect pattern (left splice): Bars step to the left at the join. (See right portion of photo below labeled as step 2)

- Incorrect pattern (right splice): Bars step to the right at the join.

(See right portion of photo below labeled as step 2)

4. Adjust incorrect calibration pattern:

Slightly loosen the upper and two lower head-mount screws just enough to allow micro-movement. Support the head; do not stress FFCs/ink lines.

- If splice steps left → nudge the upper end right or lower end left.

- If splice steps right → nudge the upper end left or lower end right.

- Movements should be sub-millimetric. Use the mount as a pivot; keep head face parallel to the carriage rail.

5. Lock-down sequence

-

Lightly snug upper screws, then lower; re-torque in cross pattern.

6. Re-print & verify

-

re-print pattern using Print Adjust button in control panel

- Repeat Steps 2–6 until all channels show straight, unstepped vertical stitching.

7. Final acceptance

- No visible step at splice under 10× magnification.

- No new banding on a 50–100 mm solid fill test.

-

Proceed to Bidirectional and Step/Color digital adjustments.

Notes & Tolerances

-

Typical acceptable splice error: ≤0.05–0.10 mm (visually seamless).

-

Always adjust physically first, then apply digital offsets only if residual error remains.

Common Mistakes

-

Over-tightening one side first → introduces tilt; always cross-torque.

-

Compensating a mechanical mis-seat with digital offsets → inconsistent results across swaths.

-

Skipping nozzle check prior to alignment → misreads caused by clogged nozzles.

Troubleshooting

-

Error persists directionally: Check for debris under head feet or uneven bracket. Reseat head.

-

Pattern changes across width: Inspect carriage rail and encoder strip for contamination or looseness.

-

Random mis-stitching: Verify platen vacuum/film flatness; check head cable seating.

Next Steps (after pass)

-

Run Bidirec Adjust, then Step Adjust, then Color Adjust ect... in Hosonsoft.

-

Save a dated Baseline Alignment Record (photo of chart + notes)